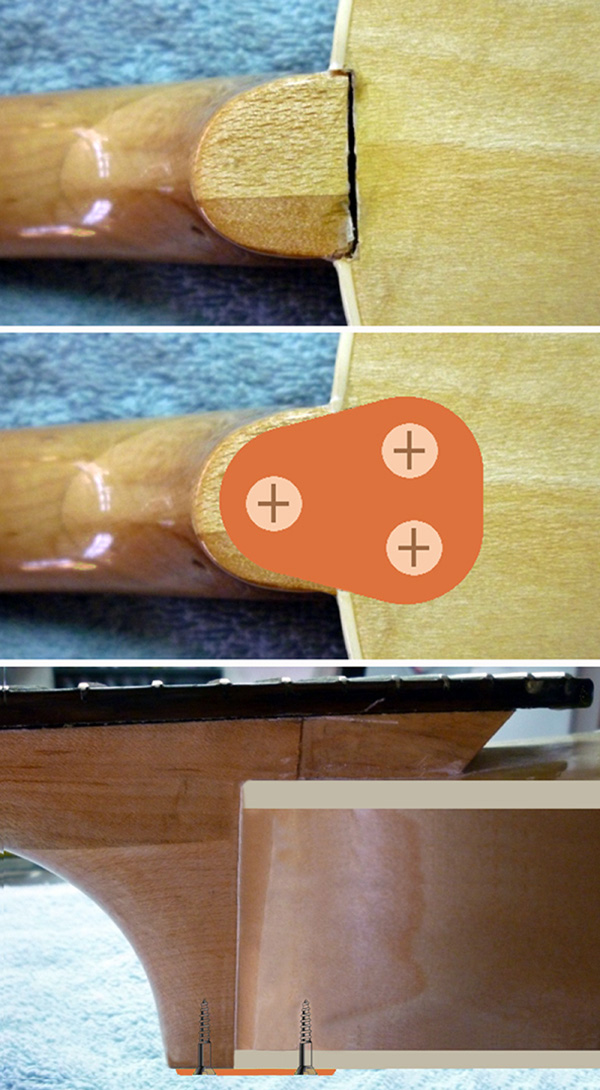

This Santa Rosa would not warrant a reset by a good luthier due it's low replacement cost. But I do likes to tinker a bit. The gap between the neck heel and body appeared a few days ago after I noticed the action was suddenly a bit high up the neck. I removed the strings right away and noted very slight movement at the joint. I cut throught the finish with an xacto and a razor saw. I confimed that the fingerboard extension goes down into or thru the ply top.

I removed the fingerboard with a clothes iron. There were no locating pins or screws visible, and no visible dovetail gap or pocket. From reading other posts after a forum search, I guess I'm gonna need to drill down into the joint between the end of the neck and the fretboard extension support and apply a steam needle. Any guesses on whether I have a mortise and tenon, shallow straigt dovetail or other joint? If dowels are present I should probably drill off-center on either side of the neck midline, right?

Thanks,

Scott

Reply With Quote

Reply With Quote

Bookmarks